PV Retrofits in the Age of Transformerless Inverters

Practical considerations for retrofitting aged PV systems with new, transformerless inverters

As PV systems age, particularly older, 600-volt systems, the need to replace failed inverters is becoming more of an inevitability for solar project owners. Replacing older, failed inverters, presents a few practical challenges however. One of them is the need to bridge older, lower voltage PV panels to newer, higher voltage inverters. You can learn more about this issue from a previous post on this topic by clicking here.

Another challenge, when looking to replace older, failed inverters is the fact that inverter construction has fundamentally evolved over the past few years. As such, the most appropriate selection of inverters you may find for such replacements are of the “transformerless” variety. In addition to the voltage mismatch, retrofits of such transformerless inverters can create grounding mismatches in the PV plant between the solar array and the medium voltage transformer connecting the plant to the grid.

Read on to learn more about the technical details of these challenges and how Alencon’s SPOT can help to uniquely resolve them.

How it Was

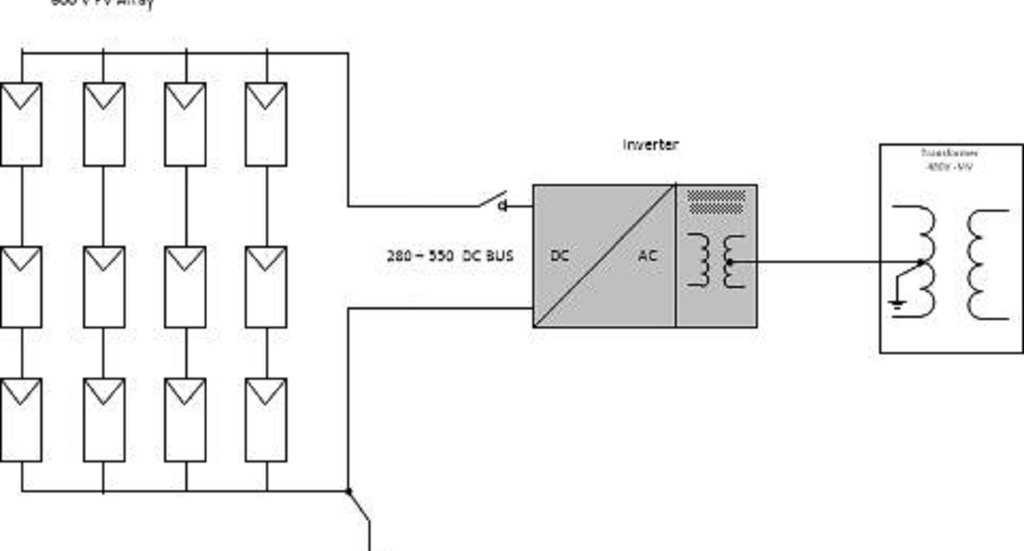

Larger scale PV projects installed between five and ten years ago typically used 600 volt rated PV modules connected to 600-volt inverters which are in turn connected to a medium voltage distribution transformer as shown Figure 1.

Figure 1 Above: A Typical 600 Volt PV Plant with its original inverter

In these older 600-volt installations, a transformer was built into the inverter. This integrated transformer carried out two functions:

a. Matched lower (208 VAC) AC voltage on the inverter output to higher 480 VAC voltage on the distribution transformer’s primary winding.

b. Provided galvanic isolation between PV array’s ground - PV arrays are generally negatively grounded, though in some cases are positively grounded - and the ground terminal of the distribution transformer. The ground terminal of the distribution transformer in these plants is usually connected to the neutral terminal of the transformer winding, i.e. grounded in the middle.

How it Is

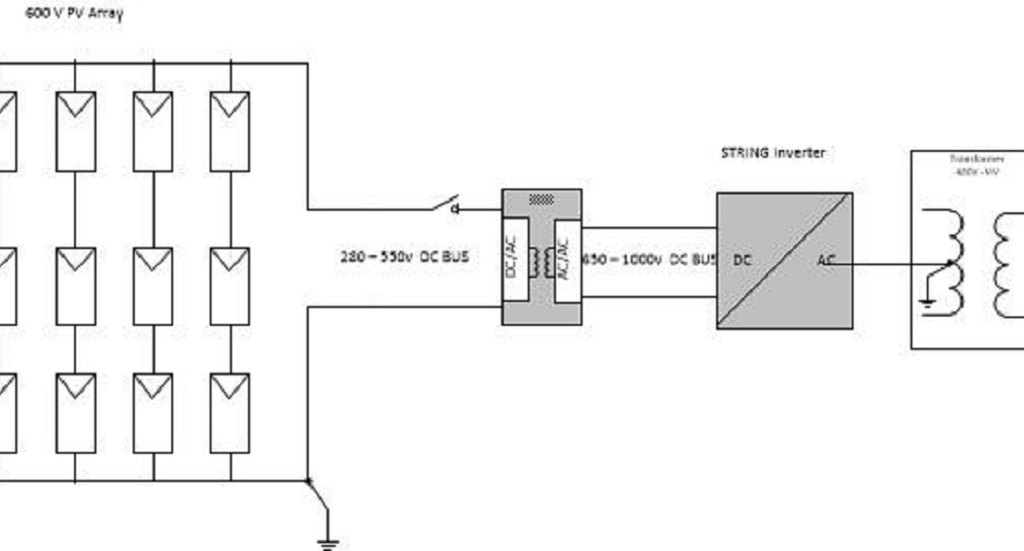

The older 600-volt inverters of yesteryear have been to a large extent replaced by more efficient, 1000-volt, transformerless string inverters that are connected directly to the MV distribution transformer as shown in Figure 2 below.

This newer breed of string inverter must produce 480 VAC on its output to match the primary voltage requirement of the MV distribution transformer. This requires a minimum DC input voltage of 680 VDC. There is generally a rule of thumb that the DC input voltage is a factor 1.35 times greater than the AC output RMS voltage. As such, these string inverters are rated at 680 to 1000 volts DC.

The Challenge of Marrying the Old and the New

When replacing an older style, 600-volt inverter with an integrated transformer with a newer, 1000-volt transformerless inverter, two issues must be considered:

a. Matching the input voltage from the older 600-volt array to the higher input voltage required by the new inverter

b. Assuring the inverter’s AC output matches the ground potential of the primary winding of the MV distribution transformer.

Neither of these two requirements can be met by the transformerless string inverter alone.

Figure 2 Above: A Typical 600 Volt PV Plant Alencon SPOTs and a new Transformerless Inverter

Introducing Alencon’s SPOT as shown in Figure 2 above can however resolve both problems because the SPOT essentially serves as a DC transformer thanks to its unique, galvanically isolated construction. From the voltage perspective, the SPOT will map the lower PV voltage range into the higher DC input range of the new, transformerless string inverter. At the same time, the SPOT will reintroduce the galvanic isolation lost when the older inverter was removed. The SPOT provides galvanic isolation between PV and the ground potential of the primary winding of the MV distribution transformer assuring that any mismatches in ground are automatically resolved. At the same time, to the extent PV panel mismatch exists, the SPOT may increase the plant’s power production by providing string level maximum power point tracking. Click here to learn more about the benefits of string level MPPT.

Watch this video to learn more about how Alencon's SPOTs can be used to replaced failed or failing 600 PV Inverters: