DC Coupling Grounded PV Systems with Floating Batteries

The Importance of Isolation in DC-Coupling Grounded PV and Floating Batteries

DC coupling of Solar + Storage on a large scale is growing in popularity as we look for innovative ways to firm up the production of solar energy and turn solar into a truly dispatchable energy resource from a merely intermittent one. DC-coupling presents the opportunity to capture energy that might otherwise be clipped during periods of over production. Additionally, DC-coupling offers a more intuitive route to installing storage into existing PV systems because it doesn’t change the AC rating of the system and hence does not require revisiting the system’s interconnect agreement in many cases.

Today however, while DC-coupling is of interest to a great many, it has been actually deployed on the large commercial or utility scale by far fewer. As such, some of the nuances in integrating Solar + Storage are not particularly well understood. One such nuance is the issue of incorporating major system components, namely PV and batteries, with different grounding schemes.

Grounding Challenges

Many installed PV systems are negatively grounded at the suggestion of the PV panel manufacturer (though some PV panels do require positive grounding). Additionally, guidance from the National Electrical Code (NEC) and certain AHJ rulings also encourage PV arrays to be grounded, as opposed to being allowed to “float.”

By contrast, today’s large-scale battery energy storage systems are generally “floating” or ungrounded. The DC-coupling approach to combining Solar + Storage requires that both the battery and the PV are placed on a common DC-bus. Doing so means making accounting for this differential in grounds.

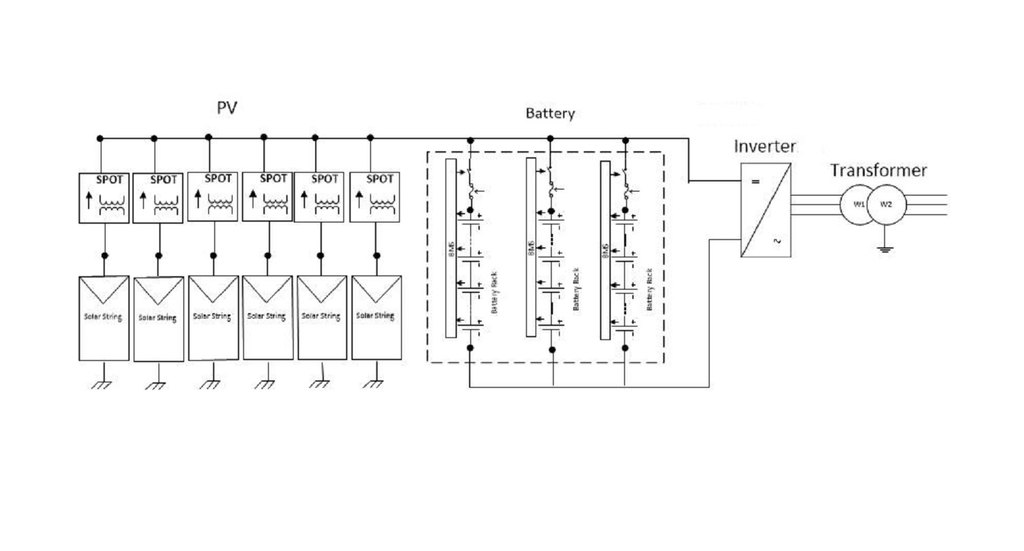

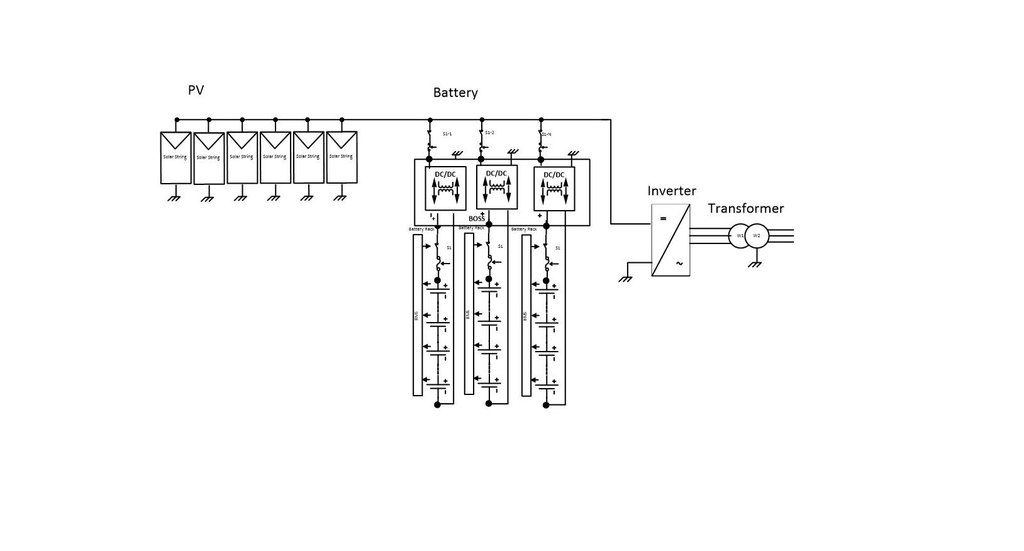

In a DC-coupled Solar + Storage deployment, a power electronics device known as a DC-DC optimizer generally creates the voltage bridge between the PV and the batteries to assure the battery receives the needed level of voltage to charge or discharge itself during the operation of the DC-coupled battery energy storage system (BESS). The challenge that this presents is that if you put a non-galvanically isolated electronic device between the battery and the PV, it means these two system components must have a common ground, which is not at all the case when the PV is grounded and the battery is floating.

For the commonly installed AC-coupled Solar + Storage systems, this issue is alleviated because these systems generally have isolation built into them because the battery and PV system each have their own inverters, which themselves are typically isolated. In many cases, such systems also have isolation transformers behind those inverters which automatically creates the needed isolation. This built in isolation, is one reason there are those who are argue AC coupling is “simpler” than DC-coupling, and they might have a good point

Alencon Solution

Alencon’s line of galvanically isolated DC-DC optimizers hit the market and resolved this problem once and for all. Here at Alencon, we address this issue by offering a range of galvanically isolated DC-DC optimizers to facilitate DC-coupling. As we see more developers and system owners looking to deploy DC-coupling, we are seeing more questions around resolving this challenge. With Alencon SPOT or BOSS products, the issue of putting a grounded PV system on the same DC-bus as a floating battery is easily handled.

Figure 1: The Alencon SPOT isolates the PV system's ground from the battery and the inverter.

Figure 2: The Alencon BOSS isolates the battery from the DC bus (PV and inverter). Additionally, the BOSS isolates individual battery racks from one another.

As such, when looking to design your next (and perhaps first) DC-coupled Solar + Storage, we strongly encourage you to consider the issue of how you plan to handle the possibly differing ground potentials of your PV array and storage systems.

See also

- How Alencon Systems' Products can be Accounted for in the Domestic Content Bonus of Inflation Reduction Act (IRA)

- The Case for Utility Scale DC Coupled Solar + Storage

- Safety Lessons from Large Scale Energy Storage Deployments

- Tired of Looking for Needles in Haystacks in Your PV Array? Learn What Galvanic Isolation Can Do for You.