How DC:DC Converters Help Give EV Batteries a Second Life

By Balancing Charge and Stepping Up Voltage, Alencon’s BOSS can turn used EV batteries in stationary battery energy storage systems

At this risk of stating the obvious, electric vehicles (EVs) are becoming more popular with high double-digit adoption growth rates forecast well into the 2030s. The heart of the electric vehicle is its rechargeable battery. As a rule of thumb, EV batteries generally last for about 5 – 8 years and typically need to be replaced when they reach a state of health (SOH) of about 70%, meaning they reach a point where they can hold 70% of the charge they could when they were new.

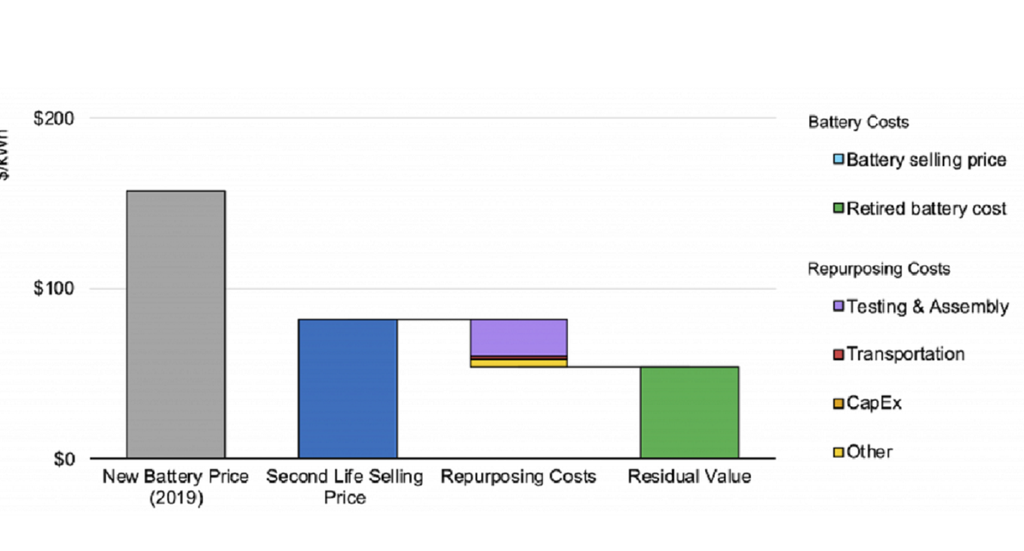

Even at 70% SOH, there is a lot of tread left on those tires! So much so, that there is a significant market opportunity in repurposing these batteries for use in stationary battery energy storage systems (BESS). Couple this with the fact that a used EV battery can cost anywhere between 25% to 35% less than a new battery module and the case for reusing them gets more compelling. A recent study from Circular Energy Storage estimated this market opportunity could be as large as $4.2 billion by 2025. This article will explain how galvanically isolated DC:DC converters like Alencon’s BOSS can help ease the transition of an EV battery into its second life as part of a stationary BESS.

Figure 1: Second life EV batteries can be an attractive choice for inclusion in large scale battery energy storage systems (BESS) because they can cost 25% to 35% less than new batteries. (Source: Ambrose, Union of Concerned Scientists, Blog, May 27, 2020)

Voltage Step Up

One of the challenges in using second life EV batteries in BESS projects is the large disparity in voltage between these batteries and today’s modern 1000- and 1500-volt inverters. Most second life EV batteries tend to have relatively low voltage charge profiles by grid scale applications standards. A typical second life EV battery may have a charge-discharge voltage between 300 - 400 volts. A typical 1000 volt battery inverter (or PV inverter when DC coupling second life batteries with PV inverters) will have an operating voltage between 550 - 850 volts, while more commonly adopted 1500 volt inverters will operate between 900 - 1400 volts. This means getting a second life battery to work with a grid scale inverter is going to require a significant voltage boost, one so large that it is out of the range of most traditional “buck boost” converters.

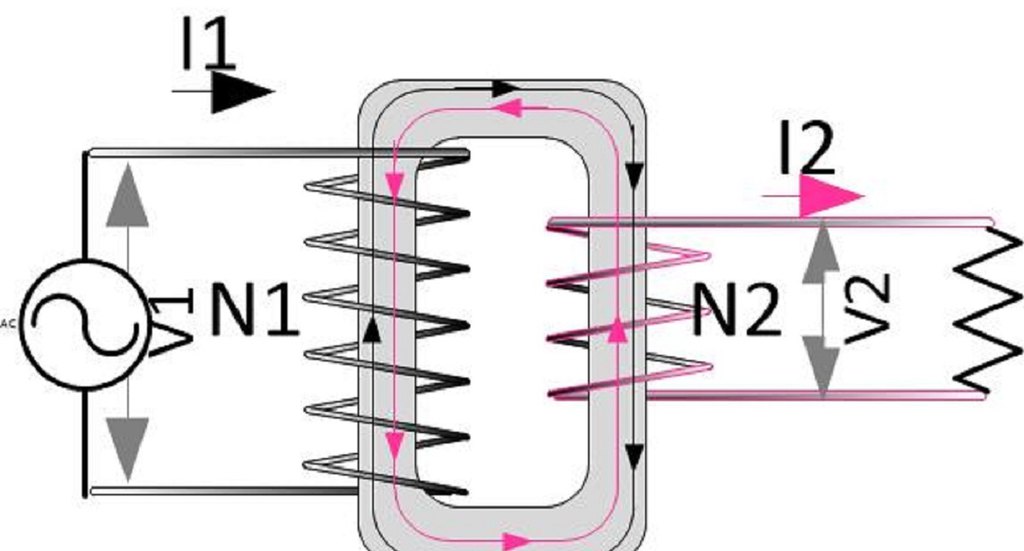

Alencon’s BOSS uses a patented, galvanically isolated approach to overcome this large voltage gap. Through the use of a unique, high-frequency transformer, the BOSS can easily boost the voltage from a lower voltage second life EV battery to a 1000- or 1500-volt inverter. This ability will allow second life EV batteries to be used with modern day, grid tied inverters.

Figure 2: Alencon’s BOSS utilizes a unique, on-board, hi-frequency transformer to map the large voltage difference between second life EV batteries and modern, grid tied inverters

Charge Balancing

To paraphrase a line from the 1990s movie Forrest Gump, second life EV batteries are like a box of chocolates from an SOH perspective - you never know what you are going to get. Since different second life EV battery “packs” can have varying SOH (after all, not everyone drives the same way!), the amount of charge they can take when placed into service in their second life can differ significantly. To get the most ‘juice’ out of a second life EV battery, you may want to consider charging each rack of second life batteries individually to assure the desired, optimal state of charge (SOC). In many, new, large-scale battery energy storage systems, new battery racks are often placed in parallel and provided the same voltage. This approach works well enough when all the battery racks have the same state of health, as is the case with brand new battery racks.

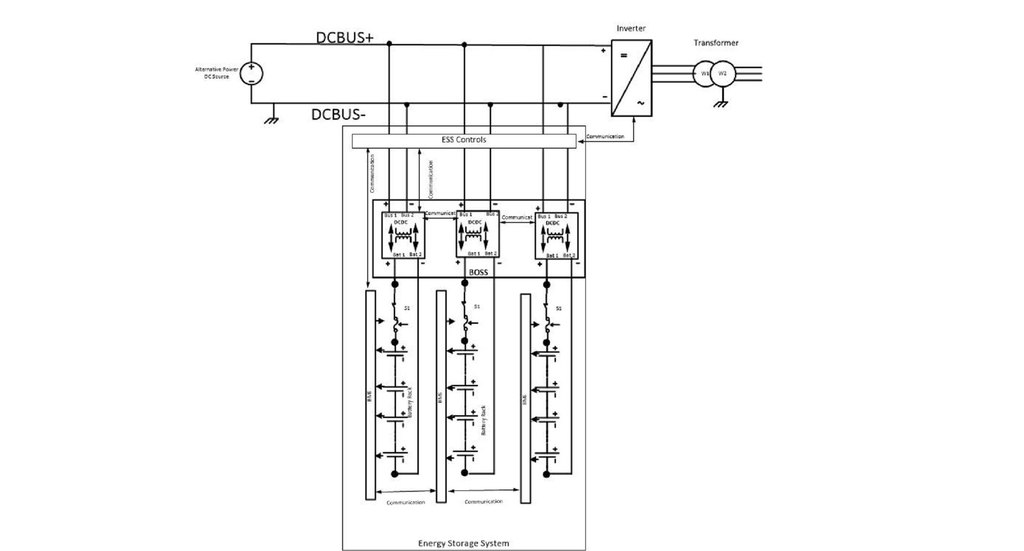

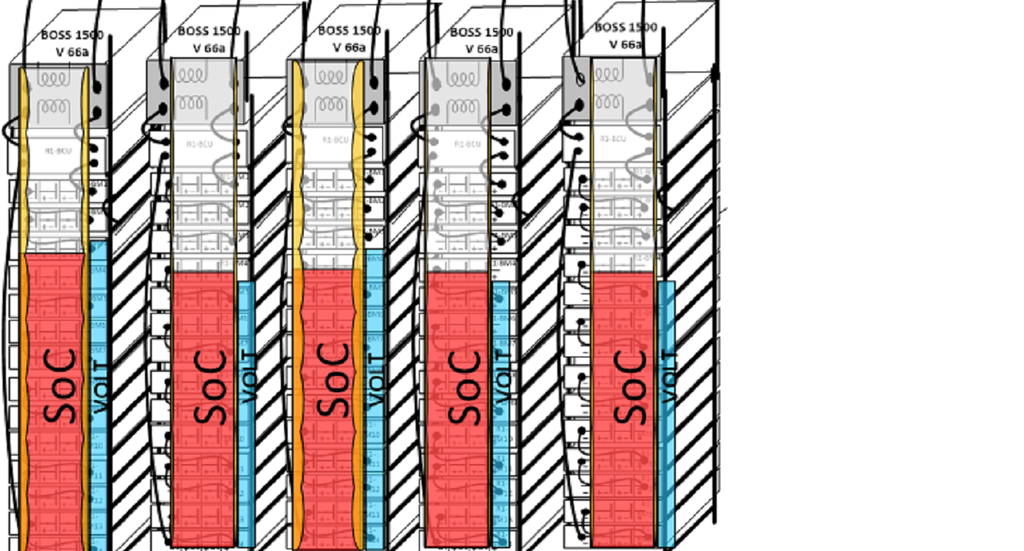

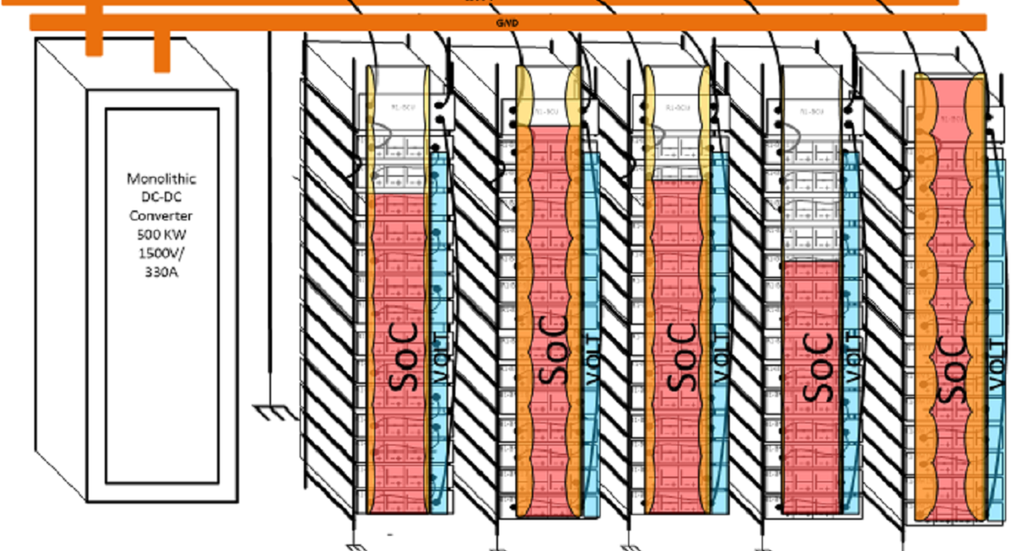

Figure 3: Alencon’s BOSS allows individual racks of batteries to charged independently to optimize their state of charge.

Placing many second life battery racks in parallel and applying the same charge or discharge voltage across all of them will quite likely cause some racks to be underutilized. This occurs because voltage dictates how quickly a battery will be charged. A battery with a “worse” SOH will “fill up” faster than a “healthier” battery. Thus, applying the same voltage across several second life batteries with varying SOH will only allow the entire system to be charged up to the level of the “least healthy” battery. The Alencon BOSS offers the ability to charge each battery rack independently. The BOSS can assure a second life EV battery lives up to its full potential in a battery energy storage system before it reaches the end of its useful life and is ready to go to its final resting place – the recycling bin.

Figure 4: As a battery’s state of health (SOH) deteriorates, the battery’s capacity to hold charge diminishes. If you think of a battery as a cylinder of energy, this is analogous to plaque building up on the walls of the cylinder, serving to decrease the cylinder’s fillable volume, or in this case the capacity of the battery to hold charge. When a battery has less capacity due to a worse SOH, it reaches its peak charge faster because it has less 'volume' to hold charge. Thie level of charge of a battery is changed by applying voltage to them. Thus, charging batteries with differing states of health with the same voltage, as is often the case with second life EV batteries, will result in uneven utilization. This uneven utilization occurs when using a monolithic charger or single inverter, as shown in the picture on the left. With the Alencon BOSS, as shown on the right, each rack can be charged individually with a separate voltage to achieve the optimal state of charge of each battery, regardless of their SOH. This rack level charging approach can make more efficient use of second life EV batteries in BESS systems.