What’s Your Energy Storage Augmentation Plan?

Ideas for how to address the inevitable degradation that occurs with lithium-based energy storage systems

If you’re reading this, you likely own a mobile phone, which means you have personally seen what battery degradation looks like over time. Large scale, lithium chemistry-based energy storage systems (ESS) experience the same phenomenon, their performance degrades over time. Every time you cycle a battery, its capacity and efficiency decrease a bit. The performance of a system one- or two-years post deployment will not be the same as on the first day the system is commissioned.

As such, when considering the deployment of an ESS, whether stand alone or closely coupled to another source of generation like solar you are going to want to make sure you’ve defined your “augmentation strategy” from the outset. An ESS augmentation strategy refers to your plan to maintain the performance of your storage system over its life by either rotating batteries in and out of the system or adding more storage capacity to the base system…or both.

Some projects may require battery replacements within 5 years, while others may take longer. Therefore, it’s important to take into account different duty cycles, technology choice, and specific use cases to determine the appropriate the augmentation strategy in order to plan and, most importantly, budget accordingly.

SOC vs. SOH

The capacity of lithium-based batteries to store and discharge electrical energy is measured in MWh or KWh. The amount of releasable charge the battery contains at any given time relative to full capacity of a battery is called State-of-Charge (SOC) and is measured in percentiles:

SOC = C(releasable)/C(max) x 100%

As batteries age over time, they experience a number of charge/discharge cycles. As such, their capacity to hold charge diminishes. The degree of degradation of the battery measured as a percentage of current full capacity to the initial rated capacity is called State-of-Health (SOH) and is measured in percentiles.

SOH = C(max)/C(rated) x 100%

To prevent overcharge of full discharge all battery racks should maintain the same SOC. This means that charge/discharge current should be controlled according to their SOH.

Future Proofing Your ESS

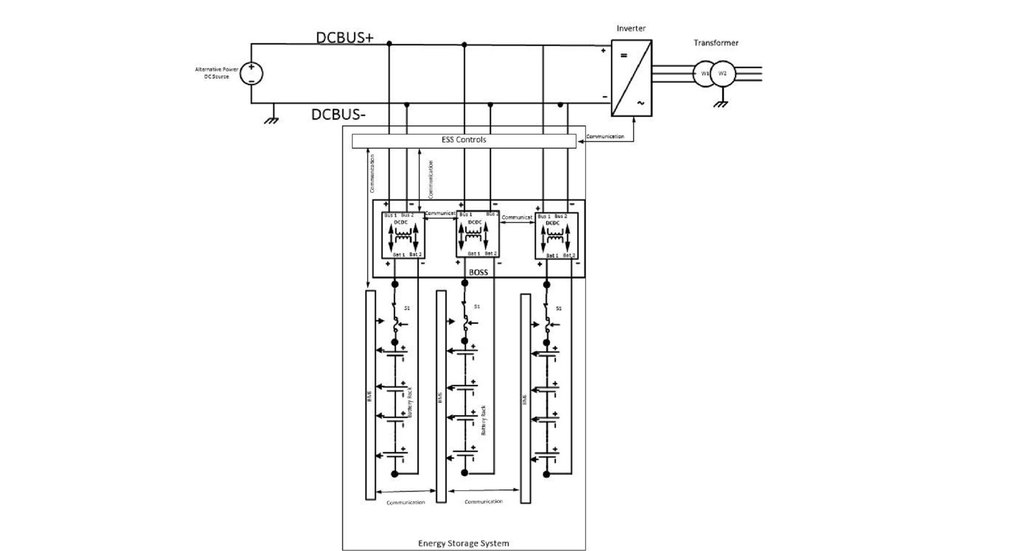

One great way to “future proof” your ESS is to consider rack level, DC-DC optimization. Here at Alencon, we have built a product called the BOSS – bi-directional optimizer for storage systems – which does just this. The BOSS serves to charge and discharge ESS at the rack level. This product was designed and built through a comprehensive stakeholder feedback process which included input from no fewer than 26 leading energy storage integrators and manufacturers. One of the key, common issues we addressed when designing the BOSS a year ago was offering our customers an augmentation friendly, future proofing strategy.

Unlike a larger, monolithic DC-DC optimizer that charges and discharges and entire container of batteries (numerous racks) all at once, the BOSS is able to manage the charge of each rack individually. The BOSS can extend the life of a battery rack by optimizing its state of charge and thus its state of health over the long haul. This feature itself helps improve project economics by extending battery rack life.

Where this approach becomes even more helpful is when it is time to actually implement your augmentation strategy. By handling the charge and discharge of each rack individually, should one rack need to be replaced with another with a different voltage charge/discharge profile, this can easily be done without any reconfiguration of the system. If your augmentation strategy calls for adding more storage over the life of the project, using Alencon’ s BOSS gives you the opportunity to add different types of batteries, either different vendor’s offerings or even different battery chemistries entirely, to the same DC-bus.

Figure 1: The Alencon BOSS is battery rack-level, galvanically isolated DC-DC optimizer that can serve as an integral part of your ESS augmentation strategy. The diagram above shows placement of the BOSS units relative to each battery rack in an ESS.

Lessons Learned from an Aging Solar Fleet

It has been said that large scale storage is at the same point on the deployment curve where solar was ten years ago. A decade into the Solar boom, we are just now learning the hard lessons of what it really takes to maintain these assets over the projected life of a project. Vendors will go out of business. Technology will change. Like for like replacements for battery racks you are deploying today may not be available when it is time to replace them.

It has been requoted so many times, it is almost cliché, but here we go (again): “Those who do not learn the lessons of history, are doomed to repeat them.” Let’s see if we can’t learn from some of the hard lessons of the past decade of Solar deployments to make the next decade of large-scale storage deployments that much more successful.