What are DC Overbuilds and Why Should You Care?

There is a trend toward ever increasing DC:AC ratios. This blog unpacks why this is occurring and how you can take advantage of this trend.

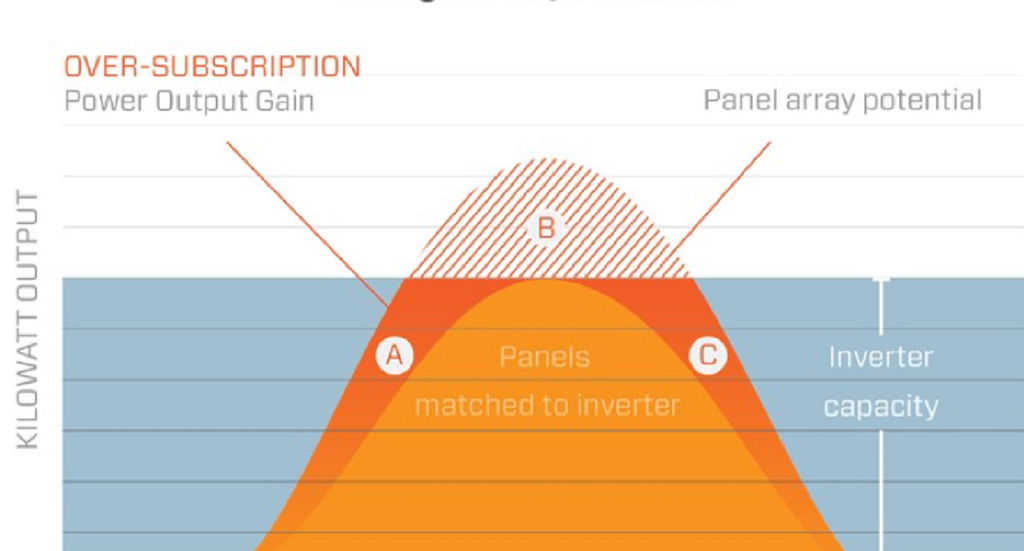

The DC power rating of a field of solar panels relative to the AC power rating of the inverter those panels are connected to is known as the DC:AC ratio. The larger this ratio, i.e. the higher above 1 this number is, the greater a PV plant’s “DC overbuild.”

In recent years, due to the falling price of PV panels and improved inverter technology, there has been a trend to increasing DC:AC ratios. Years ago, PV plants were designed with modest DC:AC ratios, typically between 1.05 and 1.1. In more recent years, DC:AC ratios for both C&I and utility scale plants have increased from anywhere between 1.5 to 1.8 DC:AC.

Today, there is great incentive for project developers to “load up” on the DC:AC ratio because the incremental cost of building more PV (i.e. DC) is quite low relative to the fixed cost of building a PV plant, i.e. development expenses and other soft costs. Additionally, with more PV coming onto the grid, AC interconnect sizes are being limited and are becoming harder to come by.

All that DC overbuild leads to the possibility of extensive amounts of potential clipped energy, PV production that is curtailed by the inverter when PV generation exceeds the inverter’s power rating. Additionally, with more plant owners now replacing failed 600-volt inverters, this offers the opportunity to reconsider the DC:AC ratios of older plants as well.

Figure 1: The diagram above shows the potential excess power that can be curtailed when using large DC:AC ratios. How best to handle this excess power can be addressed in a number of ways with Alencon's products. (Diagram courtesy of Ginlong Solis)

Here at Alencon, we find ourselves working with our customers to help them make the most of maximizing the benefit of their DC overbuilds. Sometimes, the solution to this problem is pairing these plants with storage using the DC-coupled technique.

The DC coupling technique of combining solar and storage allows excess solar generation to be diverted into a battery during periods of overproduction. This captured generation can then be discharged later in the day or in the evening to smooth out the production from a PV plant, turning an intermittent energy resource like solar into a truly dispatchable one.

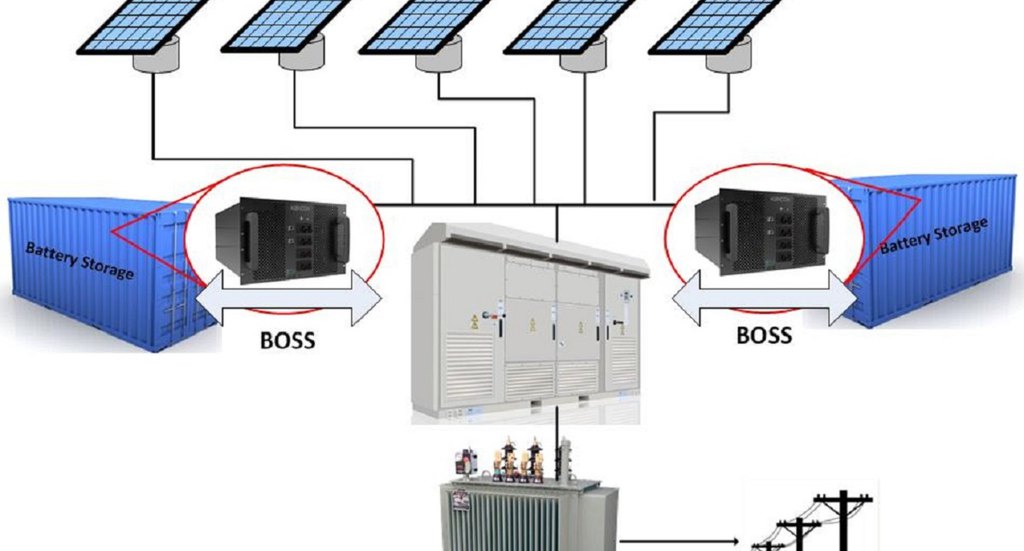

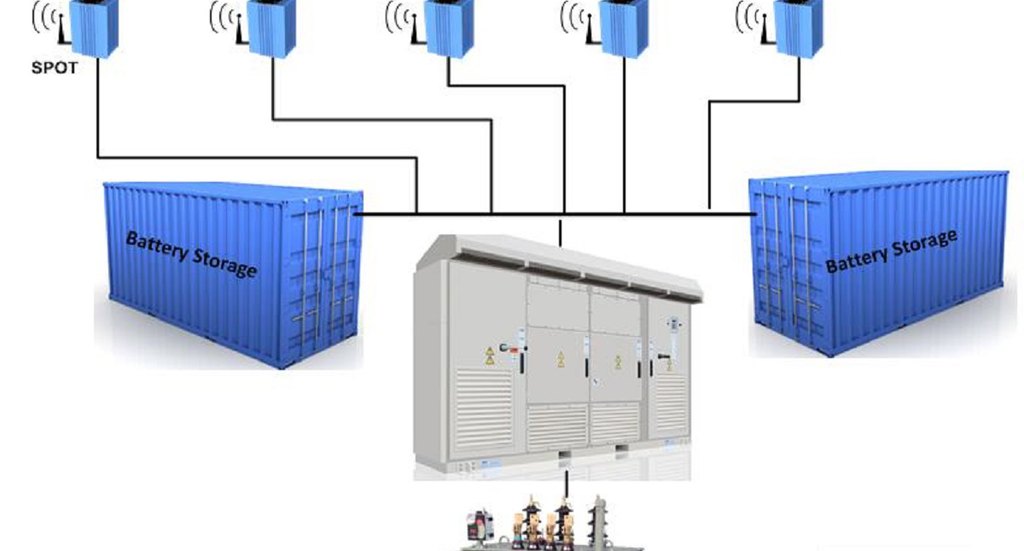

In such cases, Alencon’s DC-DC optimizer products, the SPOT and/or the BOSS, can be great solutions for coupling solar and storage on the DC-side of the inverter. The SPOT uses a “PV Centric” approach to DC coupling, meaning it sits between the PV panels and a DC-bus connected to a battery and an inverter. The BOSS uses a “Battery Centric” approach to DC coupling, meaning it sits between the battery and a DC-bus connected to a PV array and an inverter. While each approach has its relative technical and economic benefits and tradeoffs, one of the decision-making criteria we here at Alencon often to use to determine which method is best is the relative DC:AC ratio. When the DC:AC ratio is above what the inverter can handle (if the inverter can do maximum power point tracking [MPPT] at all…i.e. it isn’t a battery inverter), the SPOT can take over the MPPT function while delivering the required voltage the battery needs to charge and discharge. Additionally, if the battery is full, the SPOT can be programmed to automatically curtail PV production to only deliver the amount of power the inverter can handle or even none at all. In this sense the SPOT can act as a dimmer switch for the PV array.

Figure 2: Alencon's SPOT and BOSS products offer two different approaches to DC coupling of Solar + Storage, which can be a great way to recapture potential clipping losses resulting from large DC:AC ratios. Which approach to DC coupling, you use, either the PV centric approach with the SPOT (picture on right above) or the battery centric approach (picture on left above) very much depends on just how big your DC:AC ratio is.

Of course, not every PV project can economically justify adding battery storage. In those cases, the Alencon SPOT can serve as a great tool to amplify an inverter’s published maximum DC:AC ratio. It should be stated that research from leading inverter suppliers such as ABB/Fimer indicates that just because an inverter can run at a certain DC:AC ratio, say 1.5, that doesn’t mean it should. Running at its max DC:AC ratio can stress an inverter excessively and shorten its expected useful life. In such cases, the Alencon SPOT can serve as a great tool for maximizing PV yield over and above an inverter’s listed maximum DC:AC ratio while maintaining the inverter’s expected useful life. The SPOT does so by working in tandem with the inverter’s MPPT function and then curtailing PV production when it rises above what the inverter can safely handle.

The fact of the matter is PV panel prices on a cents per watt basis are going to continue to fall which means you can expect that DC:AC ratios are going to continue their upward trajectory. How you choose to deal with this trend could be an important part of your company’s solar deployment strategy going forward. Here at Alencon, we are heavily focused on the issue of dealing with DC overbuilds and can help you navigate the most optimal plant design solution to help leverage the benefits of ever-increasing DC:AC ratios.