The Anatomy of a PV Retrofit

Considerations in Executing a PV Retrofit

By:

Kevin Wright, President and Founder, ProtoGen Energy

Hanan Fishman, President, Alencon Systems

There are any number of reasons you might want to retrofit an existing industrial or utility scale PV system. Perhaps the system is underperforming due to PV panel damage or degradation. Perhaps you are having fault states like arc and ground faults that are causing both underperformance and safety concerns. Maybe your central inverter just died and you need to replace it. Or perhaps you are looking to add to storage to the system to combat the effects of DC clipping at peak sun and better smooth out energy provision to the grid versus customer energy demand.

No matter what your rationale for performing a retrofit, you need to understand that doing a retrofit to a PV system is quite different from new construction. The profit margins are going to be a lot thinner and ROIs are going to be even tighter than in new construction. And, in many ways, the stakes are going to be higher because with a retrofit you’ve got to factor in system downtime, whereas with new construction, you are not generating power until the system is turned on. As such, you want to have a very close look at hard costs versus soft costs.

Hard costs are generally defined as the hardware you need to deploy in the retrofit, where as soft costs are the other costs involved in actually executing the retrofit. Soft costs can also be hidden costs, which makes them all the more important think about. Soft costs are also measurable in different ways, namely in both money but also in time. For example, one soft cost of a retrofit may be permitting from the appropriate authorities (often referred to as the AHJ – Authority Having Jurisdiction). Permitting may not be an expensive proposition in terms of dollars, but it can take time, all of which needs to be factored into your project schedule. Other soft costs also include installation and engineering labor. Not to mention project management.

Against this backdrop, probably the #1 key to executing a successful retrofit is to follow well proven Pareto Principle – otherwise known as the 80/20 rule. The key to pulling off a PV retrofit in a cost and time effective manner is to think in terms of 80% planning and 20% execution. In our experience, if you can maintain that proportionality, you should be able to set a similar target for your percentage of hard costs (installation gear) to soft costs (mentioned above).

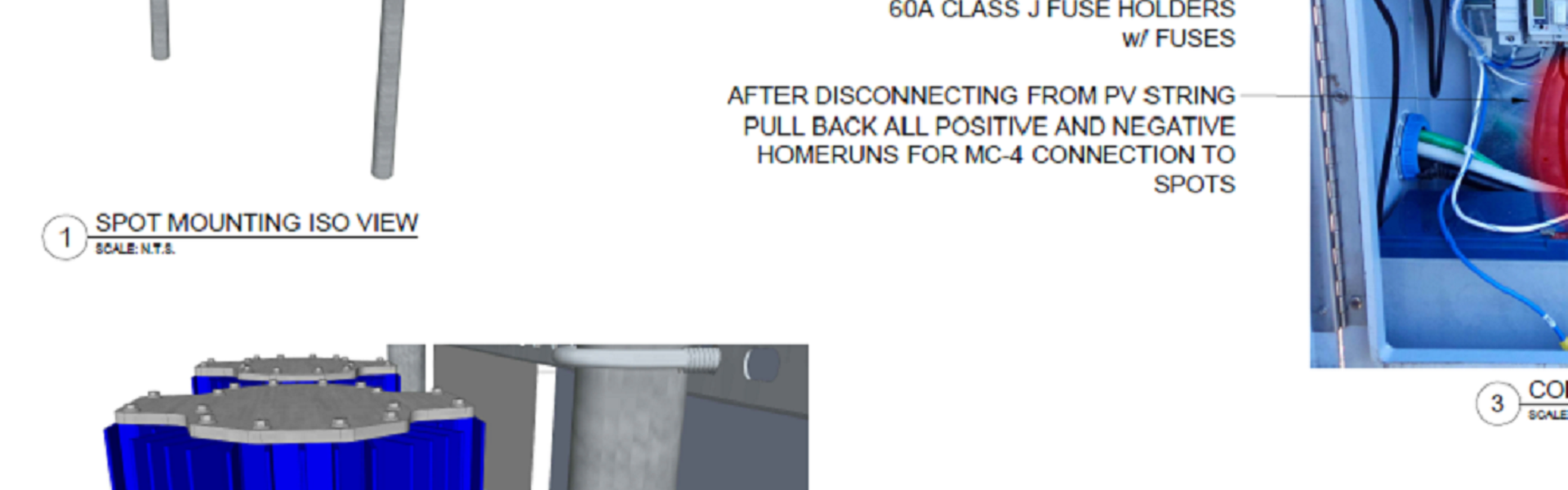

Of course, a major factor in achieving such a result is to work with professionals who have done it before. While that might seem an obvious point, PV retrofitting is a rapidly evolving field and the line between retrofitting and O&M activities can be pretty grey. This is why Alencon has partnered with Protogen to execute a number of retrofit projects. While Alencon’s SPOT has been specifically design to minimize retrofit costs by offering as close to a “plug and play” PV retrofit solution as possible, the team at Protogen has the knowledge and experience in PV electrical construction to pull off such projects in a cost effective manner.

As a helpful guide, if you are considering a PV retrofit, you will want to develop the following checklist during the planning process:

1. How much is the equipment going to cost?

2. Have I considered the all the elements of ROI that go into the project including production incentives and potential tax credits like accelerated depreciation?

3. What sort of engineering analysis will I need for the project? Structural? Electrical? Anything else?

4. Will the work require a permit? If so, who is the AHJ? What do they need to approve the project (i.e. stamped and sealed drawings or just a statement of work?)

5. What sort of certifications will be need for the equipment being installed (i.e. UL or NEC)?