Alencon Systems LLC will showcase the newest generation of its DC-DC optimizer at the PV Operations & Maintenance USA conference December 6 and 7 in San Francisco, CA. Alencon’s String Power Optimizer, the SPOT, is the PV industry’s most powerful and versatile DC-DC optimizer for large commercial and utility scale applications. The latest version of the SPOT features a more rugged, low profile design along with a number of unique power electronics features to allow both new and existing PV plants to generate more energy while also streamlining their operations and maintenance (O&M) activities. Alencon’s SPOT can improve the yield of PV plants from anywhere 5 – 10% on average.

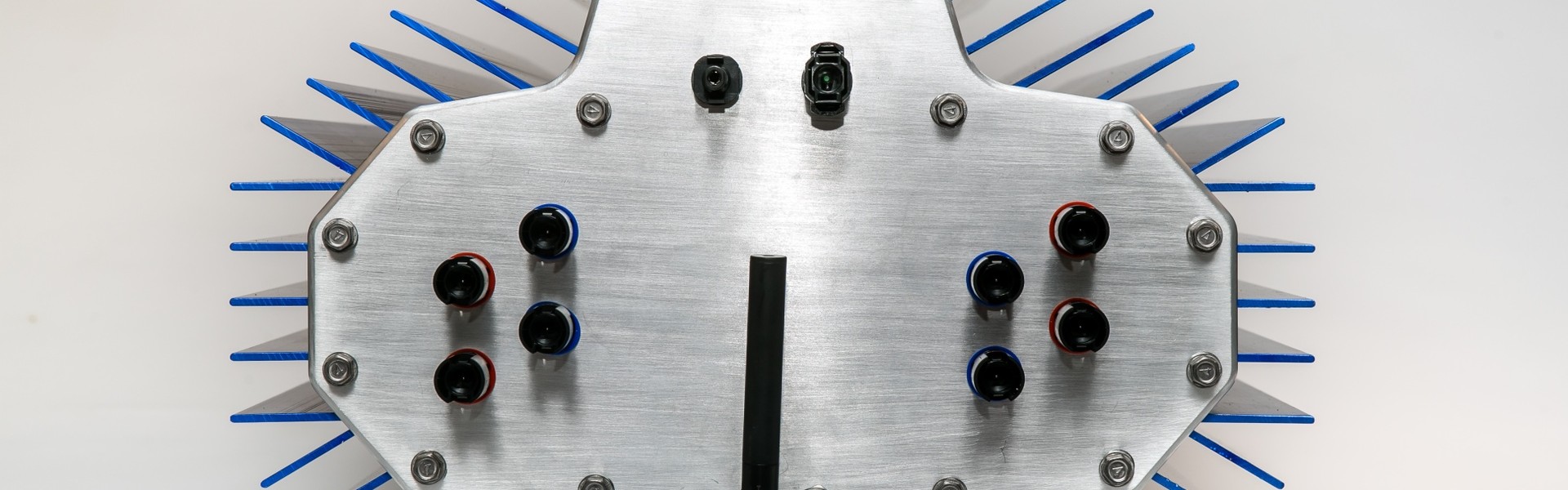

The latest version of the SPOT, the fourth generation of Alencon’s DC-DC optimizer offerings, includes a variety of enhanced features to previous versions of the product. Its NEMA4 enclosure has been recast to make it more rugged yet lighter weight and thus easier to install. The SPOT’s power electronics are the most sophisticated of their kind found in the PV industry today. The 25 KW unit allows maximum power point tracking (MPPT) to be performed on four PV strings at once, twice as many as any similar device on the market today.

“Our newest SPOT model comes to the market at just the right time for the PV industry,” says Alencon President Hanan Fishman. “As our PV assets age and degrade, a cost effective, performance enhancing solution like the SPOT is absolutely paramount to assuring the continued viability of our nation’s PV assets. Clearly, there could be no more appropriate forum to launch this new product than at a conference solely focused on O&M and PV plant performance.”

Galvanic Isolation: Alencon’s Unique Solution for Better PV Plant Performance

Alencon’s SPOT provides complete galvanic isolation between PV strings and the inverter. This unique feature makes the SPOT an incredible tool for O&M because any arc or ground faults that occur with a PV string can be isolated from the rest of the solar system. Additionally, arc and ground faults can be quickly traced to the exact PV string where they are occurring which means maintenance can be more efficiently deployed and repairs can be safely done on one string while the rest of the PV plant continues to produce power.

Voltage Step-Up: Lower Conduction Losses, Better Inverter Performance

Alencon’s SPOT allows for a broad range of both input and output voltages, so it can be deployed to improve the performance of any PV plant, irrespective of its age. By stepping up voltage on the output, the SPOT is able to markedly reduce conduction losses. Additionally, by feeding a central inverter fixed voltage, the SPOT will allow a central inverter to run much more efficiently by providing it the level of voltage that allows it to perform at its highest rated efficiency.

The PV-IoT™ for Performance Monitoring and Control

In addition to providing a number of energy production enhancing features such as granular MPPT, galvanic isolation and voltage step up, the SPOT is also a very unique PV plant performance monitoring tool. The SPOT offers continuous, wireless communication to a central aggregator, so the performance of a PV plant can be studied down to the string level. The SPOT is an Internet-of-Things (IoT) ready device. By applying the PV-IoT, the Photovoltaic Internet of Things, the SPOT allows PV plant owners to assure their assets are operating at peak performance.

More on Alencon

Alencon’s solutions for ALternative ENergy CONversion provide high modularity and scalability for systems from several megawatts to several-hundred megawatts. By helping to dramatically reduce balance of system costs, and increase power production through new inverter and energy harvesting technology, Alencon helps advance the state of the art and increase the financial viability of solar power. Headquartered in Hatboro, Pennsylvania, has been building PV power conversion hardware since 2009, drawing on the combined decades of power electronics experience of its engineering team.